Innovations creating customer value

For 160 years we have been developing unique materials and alloys and will continue to maintain a strong focus on R&D to broaden our portfolio in line with high growth areas. We have control over the entire supply chain – from R&D to melt to finished product, offering our customers a “one-stop” shop.

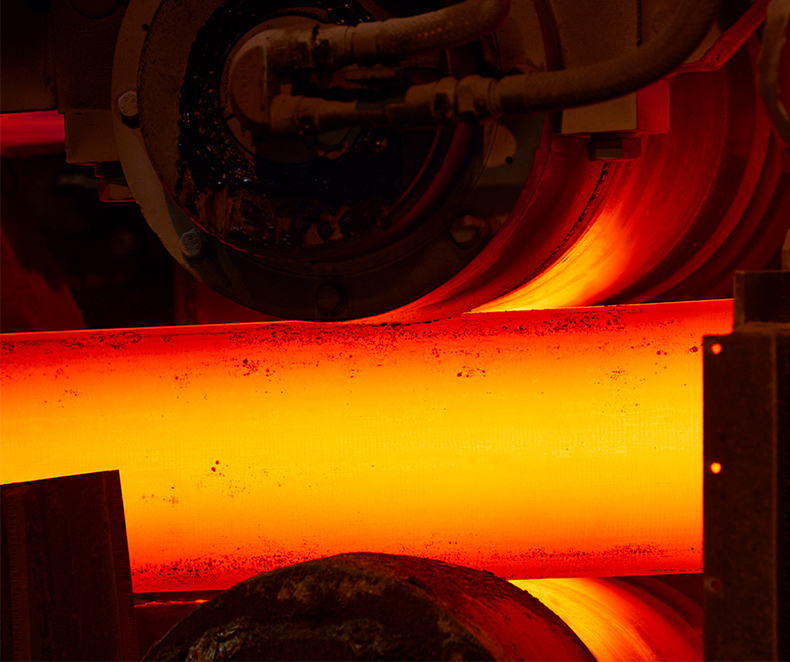

The strategic partnership Kanthal has developed with Hybrit (an initiative by SSAB, LKAB and Vattenfall) moves steel towards a completely fossil-free value chain. The initiative in Sweden aims to develop the world’s first fossil-free steelmaking technology. Kanthal has developed a large-scale electric heating solution for the project that heats large volumes of hydrogen gas up to 1,000°C (1,832°F). The new, scalable technology has the potential to be used in the cement, petrochemical and other energy-intense industries.

During the year we launched Freeflex™, a hardened and tempered martensitic stainless compressor valve steel with a unique chemical composition. This next generation of compressor valve steel enables our customers to develop more energy-efficient compressors while also using less material to produce the compressors. We see a growing demand for white goods and home appliances and will continue to develop new materials for this industry.

In 2021, our production unit in Zhenjiang, China worked closely with an equipment provider on the Spiral HX technology. This high-pressure, high-efficiency twisted spiral heat exchanger, mainly targets the chemical, petrochemical, and gas segments. The key challenge for the customer was to create long, seamless thin-walled tubes, which can be bent and twisted, suitable for high-pressure equipment within a hydrotreating unit. This project will accelerate the Spiral HX technology adoption into critical equipment supporting efficiency improvements and energy savings for end users.